|

來自意大利的全自動鋼桶縫焊機:印涂板焊接+焊縫補涂

文/鳳巢

(點擊上圖查看視頻)

鋼桶焊接設備的新設計:全自動轉換系統

提高效率的創新設計:C.S.A.F.系列鋼桶縫焊機

From the very beginning of its history, GS&Thas completely re designed the drum welding machine as known so far, byintroducing major improvements in most of the its parts, thanks to theextensive experience coming from many years operating in this field.

The main guidelines and concepts which arepresent in all our machines are:

-Robust construction and efficient operation

-Proven technology with innovation in materialsand layout

-Accessibility in all parts thanks to openmachine layout

-Simple and trouble free adjustment operation

-Reduced maintenance requirements

-Compact dimensions

-User friendly controls

-Extensive use of commercial first qualitycomponents

-Top quality in finish and detail accuracy

-Solutions for energy saving (frequencyconverters) and time saving (automaticchangeover) operation

-Maximum flexibility of the equipment in allworking conditions

For example GS&T drum welders are fit withroll former unit extremely accessible and easy to adjust, including containingcradles easy and quick to remove in case of accidents. By reducing the overalldimension of the machine, we also have shorter bus bar and the transformercloser to the welding heads, to increase energy efficiency.

The driven welding roller is fit with directgear (no chains or belts) to reduce wear, maintenance and increase rotationaccuracy.

However, one of the most important designimprovements has certainly been the new concept in the calibration tools changeover. The multi-diameter calibration tool has proven very successful amongstour customers, and it is easy to understand why.

Old concept: New GS&T concept 1calibration tool for 1 diameter 1 calibration tool for 3 diameters

This tool improves dramatically the flexibilityof the line in terms of time savings (no operator intervention) and costreduction (no more many single diameter calibrations) when you need to producedifferent drum sizes on the same line.

Specifically, this type of multi-sizecalibration is adapted to producers of special products like conical drums: itis possible to switch from Ø 530mm to Ø 571,5mm in about 2 minutes withoutany mechanical intervention or tool adjustment.

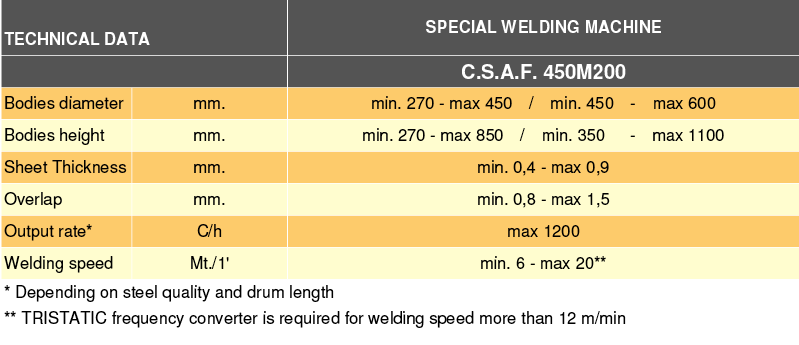

Special welding machineC.S.A.F. 450M200 for steel drums and pails

Thanks to its extensive experience in the supplyof standard steel drum welding machines for high speed lines, GS&T has beenpushing even further the concept of flexible operation, developing one of themost innovative equipment of this kind ever seen on the market, and a uniqueachievement so far world wide.

The fully automatic drum welding machine type C.S.A.F.450M200 for the longitudinal welding of steel drums and other metalcontainers of medium and large size is the ultimate result of the latest designtrends in this field. Operation flexibility has been the keyword from the verybeginning of this challenging Project. The C.S.A.F. 450M200 is suitable for production ofsteel drums and pails, when fast and trouble free changeovers are a must in theproduction time schedule.

In fact this unique machine is able to perform automaticallythe complete size changeover -including multi-size calibration crowns withhourglass rolls -with no need of any tool or key or manual interventionwhatsoever, in less than 2 minutes. The machine is equipped (mounted on board)with 3 sets of calibrations that contains other 4 size tools for differentdiameters: in its most complete configuration it makes the possibility in totalto produce nr. 12 different drum diameters by selecting from the control panelonly.

By simply entering the new production code inthe control display, all the machine working parameters are automaticallyupdated: welding pressure and voltage, roll forming radius and speed, sideguides position, cradle setting, shuttle speed, etc. thanks to its many servocontrolled axis. Between the main features of this machine are the high outputcapability and the process reliability and consistency.

GS&T has developed intuitive controls with graphictouch screen operator panels, where words (language) is mostly replaced byinternational symbols, while machine alarms and diagnostic messages areimmediately accessible.

The C.S.A.F. 450M200 can be equipped with manyoptional items to improve process performance and integration to the upstreamand down stream equipment. For example, the new TRISTATIC three phase staticfrequency converter guarantees major energy savings, process flexibility andextended welding possibilities in many different working conditions. Alsodestacker and feeder systems are available from GS&T, amongst the manyoptions.

|